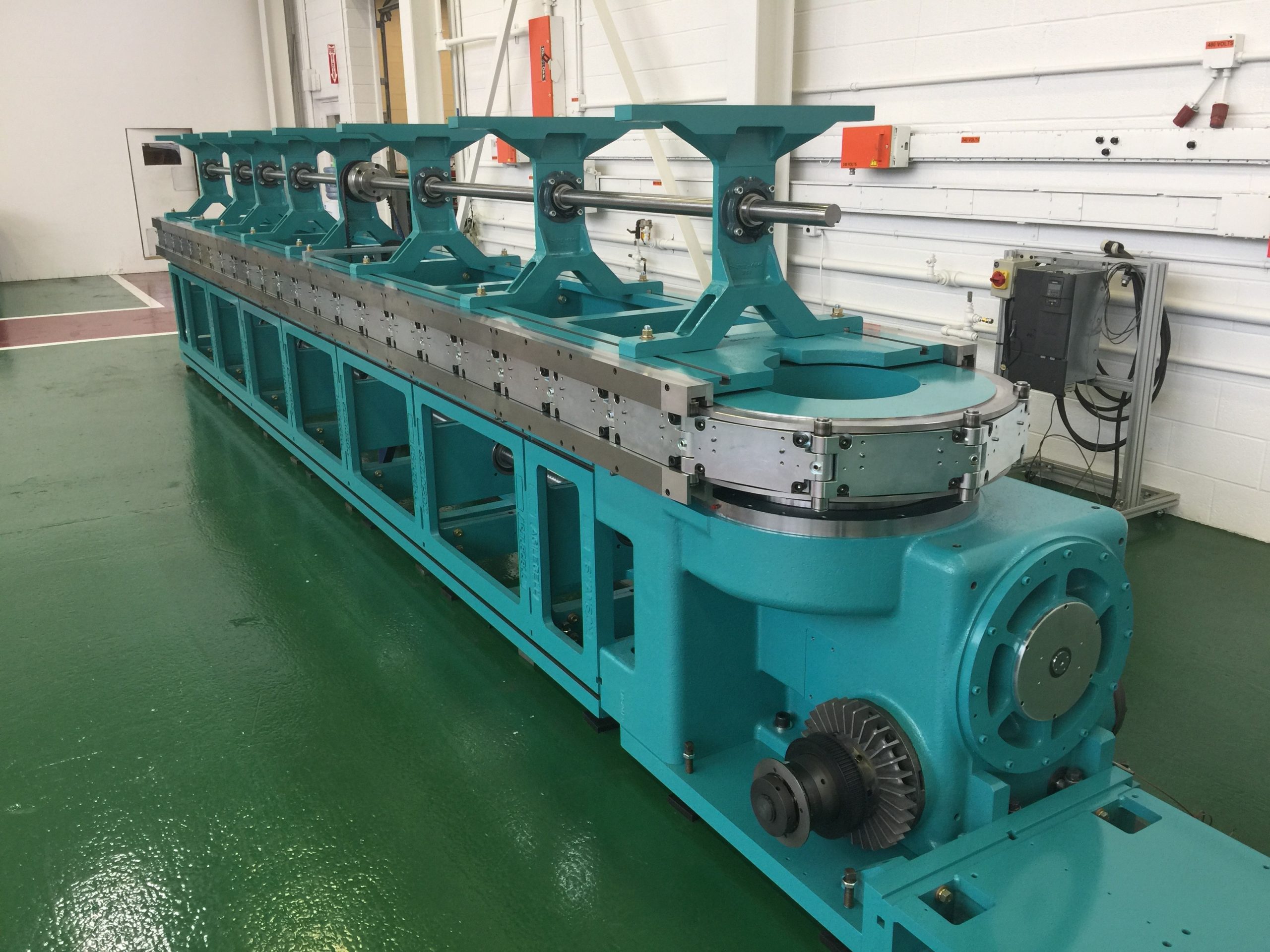

The foundation of the Agiletran is the 36” (900 mm) support structure, which is available in two widths. With its cast ductile iron construction and precision machined features, it is dimensionally interchangeability with each structure individually serialized. The Agiletran can be made in virtually any length. It is easily broken down for shipment and plant installation.

Agiletrans, in carrousel configuration, are equally friendly to both robotic tooling and cam synchronized tooling, and even hybrid combinations.

All tool mounting and precise locations is accomplished with the unique Swanson T-key arrangements on the top and side tool plates.

Companion L-2 and L-3 cam index drives are self-contained and can drive power-take-off shafts for heavy loads and high speeds, eliminating all outside mounted reducers, couplings, shafting, and pillow blocks, with a 3” diameter power take off (PTO) shaft on the centerline of the machine.

Link sizes are available from 3” (75 mm) to 12” (300 mm): all individually serialized and 100% dimensionally certified. Swanson-pioneered precision links are proven reliable after tens of millions of production cycles.