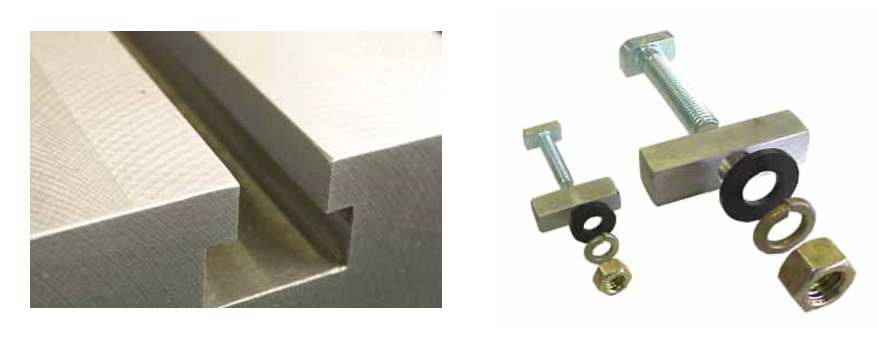

The fundamental fastening means inherent in Precision Link Agile Chassis components is the precise T-key arrangement. This patented feature utilizes an accurately machined key with a close tolerance keyway in combination with a “T” slot. Running full length in all Precision Link Agile Chassis platforms, the T-key slot permits unrestricted mounting and locating of tooling anywhere along the length of the machine, thus eliminating critically located tapped and dowel holes: a great savings in machine design, time to release drawings, and reduced assembly/development.

T-key design permits simple assembly, disassembly, and changes of tooling positions: all with the tightening or loosening of a single nut.

Precision Link Agile Chassis platform components are “fastened” together with T-keys and bolts, thus enabling virtually any configuration, length, or combination. The absence of tapped holes and screw fasteners encourages expansion/contraction/redeployment; and preserves the integrity of all Agile components.

Swanson T-keys come in two standard sizes: 0.750” and 0.375” with corresponding T-bolts. The fastening force of one, occasionally two, T-keys far exceeds that of four screws and two dowels.

In instances where it is needed to regain position after temporary removal, a simple external “dummy” T-key, can be added.