Precision Link Conveyors vs. Asynchronous Systems

Before it is possible to get into the details of tool design for assembly or process equipment, it is necessary to choose the machine transfer system that best matches the job requirements. Accuracy, station integration, line balancing requirements and index/dwell ratios will have a major bearing on the final machine capability. In this brief article, we will explore the benefits of a synchronous precision link conveyor vs. palletized asynchronous systems.

A Swanson precision link conveyor is the best choice if the part must be rigidly held in place during assembly, and if your application is high speed and requires a high level of location accuracy.

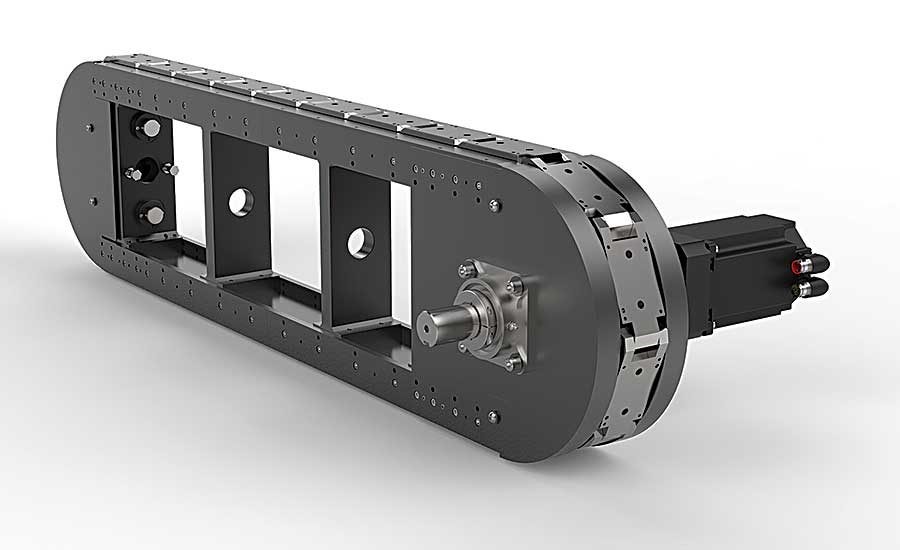

Precision Link Conveyor

The most common type of linear indexing system is a precision link conveyor powered by a barrel cam or servo motor indexer. This type of conveyor consists of precision machined links that are joined together by a precision ground shaft. The “link chain” rides in tracks, constrained by precision bearings between two large sprockets.

Advantages of a Precision Link Conveyor

The cam-driven precision link conveyor shown above, is the best choice if your application has the following important criteria:

1. The Precision link conveyor is capable of high production rates

2. The Precision link provides much better accuracy for fixture/part location.

- Layout of work flow in the plant is optimized.

- The Swanson precision link conveyor is modular and therefore is expandable.

- Better tooling motion dynamics are possible on a precision link conveyor.

- Built-in intermittent motion provides dwell time needed to process the part

In a facility with narrow aisles, a precision link conveyor is often a better fit. This type of system optimizes space by placing stations on both sides of the conveyor and allowing tool mounting in the center area. Our conveyor is modular and easily expandable, like inserting leaf’s in your dining room table to make it larger. If the assembly process requires more steps or if product volume increases, the manufacturer can begin with a small Swanson Agile precision link conveyor and expand it to meet future volume demands.

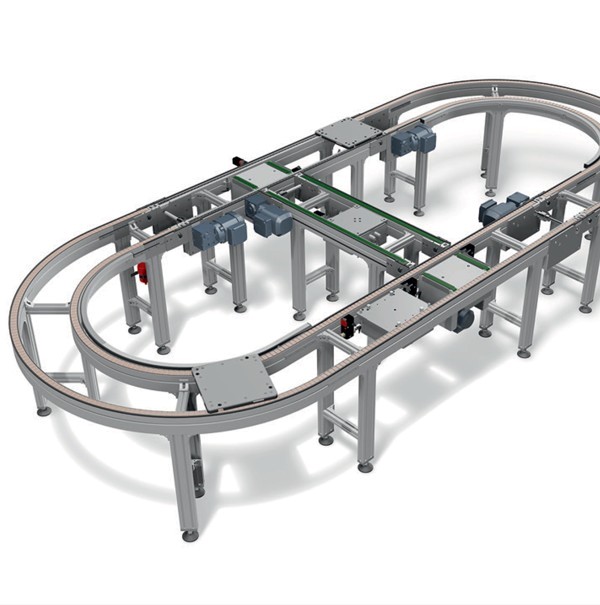

Asynchronous Systems

Advantages of Asynchronous Systems

Manufacturers often use asynchronous systems when both manual and automatic operations are required or when there are different cycle times for different process steps required in processing the part assembly. For example an asynchronous palletized carousel movement, which can employs a continuous drive motion control may consist of 10 processes, nine of which take 4 seconds to complete before a final 15-second inspection process. In a fixed system, the inspection process would be conducted on a one-by-one basis, with subsequent parts waiting in line. With asynchronous movement, four finished parts can move into the test bay at the same time and be tested simultaneously. An asynchronous movement, which can feature both fixed or programable automation, can allow products to be simultaneously worked on and allows multiple tests to be done with one machine rather than off loading the part to a test loop.

Asynchronous movements are accomplished by a continuously moving transport conveyor. This conveyor can be a conventional chain-link conveyor, a flat top chain conveyor, a belt conveyor, or a magnetic conveyor system that has been designed to best suit the application requirements. The newer magnetic conveyors can more accurately control the movement of the fixtured part pallet. The benefits of the magnetic systems which can feature either synchronous or asynchronous automation tooling, are that they can produce faster line speeds, are more predictive, require less frequent maintenance. They are significantly smaller than traditional chain-link conveyors, are able to be programmed around the process, and have push-button changeover capabilities that eliminate the need for change parts.

Disadvantages of Asynchronous Systems

The main disadvantage of an asynchronous system is slower production rates. The other main drawback in asynchronous systems is that in-station tooling is more complicated and may result in less accurate location of the parts to be assembled. The part assembly must sometimes be removed from the transport pallet in order to work or test the part being assembled.

In more recent asynchronous systems, there are often individual programable logic controllers for each station, which can results in higher initial capital cost.

Precision Link Conveyor drive considerations

In manufacturing operations that require a precision link conveyor, the dominant motion control technology has been based on the barrel cam indexer. In recent years, however, servo driven technology using a constant lead cam has grown in prominence. The constant lead cam is giving manufacturers a flexible alternative to the conventional fixed barrel cam drive. In this section we will explain the benefits (and potential drawbacks) of each system to help you make a more informed decision.

Defining terms – Barrel Cam index drive

A barrel cam indexer is a mechanical automation component that has been manufactured to produce an accurate and repeatable intermittent motion. The cam has two distinct operating sections:

- Index cam section: The number of degrees on the 360° cam that are used for moving the part fixture into its assembly or process position.

- Dwell cam section: The remaining number of degrees on the 360° cam that are used to maintain the part “in-station” where no movement occurs.

In other words, if the indexing operation calls for the cam to rotate 90 degrees and then stop, it is cut in such a way that those operational parameters are achieved every time. The motion cannot be changed. The barrel cam has been the technology of choice for indexing operations for decades. As such, it has gained a loyal following among machine builders that favor a mechanical design. It is a “tried and true” technology that is both robust and low maintenance.

Advantages of barrel cam index drive:

- Since indexing systems that use barrel cams are mechanical in nature, machine startup is less involved because the cam controls all movements. Simply power up the conveyor and the cam reliably delivers what it has been designed to provide. No programming, decision making or system debugging is required.

- Because of the way the cam is machined, when it comes to a stop, it is locked into that position, without the chance that ancillary movement will occur, i.e. minimal “lash”

- Fixed indexing systems are robust and can easily handle high load capacities.

- Maintenance is simple. All the operator has to do is change oil in the cam box after a predetermined number of hours of operation and grease appropriate movements.

- On high speed assembly machines the barrel cam can also be used to actuate process tooling. This feature results in extremely reliable equipment with minimal down time.

Disadvantages of barrel cam index drive:

- Barrel cam systems rely on hard automation to operate, meaning that if the cam is designed for a certain movement, that’s the only way it can ever be used.

- If parameters of the indexing operation need to be altered (for example, if a new part is larger than the previous one), that can’t be accommodated without changing the barrel cam. The indexer will require major modifications.

Defining terms – Constant Lead Cam with servo motor drive

- By comparison, the index characteristics of the constant lead cam are not determined by the way the cam has been cut. Rather, the characteristics are determined electronically by a programmable device, in most cases, a servo motor. Instead of having the indexing and dwell times built into the cam, the constant lead cams have a programmable indexing period. The dwell period is determined electronically by shutting down the drive motor.

- The servo drive is always reading the motor’s encoder, comparing the current position against the programmed position and making corrections. This approach results in a programable index time and programable dwell time.

- One potential negative results from the “life expectancy” of the drive components. In general the drive chain is robust, but they have a finite life due to the constant start/stop of the motor.

Advantages of servo motor drive:

- Some automation systems require a certain task to be run constantly for a year or longer, but then it will need to be modified, for example from a 90-degree index to a 120-degree index. In this case, the servo motor can simply be reprogrammed with the new parameters, whereas the mechanical system with a barrel cam would have to be replaced or rebuilt.

- A servo system can be configured to work with different part sizes just by selecting a different program. The motion is controlled by the servo motor.

- The servo motor can monitor how much power is being consumed. That information can be fed to a PC that accumulates the data and can create a report on variables like power demand, uptime and downtime, displacement rate, velocity, and acceleration and deceleration time.

- The use of a central programmable controller (to control the servo motor) makes the operation of these systems more predictive. That may sound counterintuitive at first, however, most machines have many axes of motion (six, eight, 10 or more). When their operation is tied to a central controller, that controller can sync and fine-tune the actions that are occurring at previous and succeeding workstations. This can’t be done in a fixed barrel cam system that has no central controller.

Disadvantages of the servo drive motor:

- Flexible indexing systems can often have a higher upfront cost than their fixed system cousins. Fixed systems consist of an AC motor, position switch and variable-frequency drive. A servo motor is more sophisticated than the typical AC motor. Because of the flexible system’s feedback capabilities, it requires additional hardware, including power cables, drives that send signals to the motor, a programmable logic controller (PLC) that coordinates its operation through the amplifier to the motor, and a more complex electronic system that drives the system’s flexibility.

- The technical skill level needed to set up the system is greater. Engineers must write a program that tells the constant lead cam when and for how long to accelerate, how long to stay at a certain velocity, when and for how long to decelerate, and when to come to a stop. In fixed systems, these parameters are machined into the cam.

- The programming can take several days and some trial and error to find the setup that best meets the needs of the end user.

- The servo motor’s continuous feedback loop, which is always seeking and correcting the position of the cam, may compromise the system’s precision. In this case, a braking mechanism can be installed on the servo motor to stop any ancillary movements.

- Maintaining a flexible system can be more challenging. Any incorrect adjustment can alter the recommended operating pattern, which can have an adverse effect on production rates and even lead to damaging the indexer.

Final Thoughts

Manufacturers that are deciding between a precision link conveyor and an asynchronous system would be wise to consider some specific questions and criteria concerning the design and expectations for their operations. These include:

- Will there be stations that have different processing times on the same equipment? An asynchronous motion system might be best for that application.

- Will there be more than one type of part processed that requires different motion parameters? This again may be better served on an asynchronous system.

- If the machine is only ever going to make one part during its lifetime, fixed motion control is the way to go on a precision link conveyor. If it’s a project where the parameters will be changed at some point, the servo motor option should be selected.

- If the part assembly and process requires a leak test or some other test requiring 5-15 seconds, then the asynchronous system may be the best choice.

- Does the part need to be rigidly held or locked in place during processing? The precision link conveyor system is the best choice if the part needs to be locked firm.

- If the accumulation of feedback by a central controller is required, then a servo motor Precision Link conveyor system is the best choice.

- Is there value in being able to more precisely control or restrict movement while in the dwell period? Again the precision link conveyor system with a barrel cam is the way to go.

- If high production rates are important, the precision link conveyor or the rotary indexer are both a valid choice, depending on how many parts are in the assembly.

Of course, there are many more questions to consider since every manufacturing operation is unique. For more information, call us at 888-654-9353.