Swanson Precision Link Conveyor – “Best in Class”

Swanson has the most application experience of any of the manufacturers of Precision Link conveyors, having built thousands of conveyors over the past 60 years. Among the many types of available linear conveyor designs, the Precision Link conveyor is best suited for assembly and process operations requiring precise location. It is also well suited for the inspection of parts. The Swanson Precision Link Conveyor delivers link positioning accuracy of ±0.08 mm (±0.003 in.) or better.

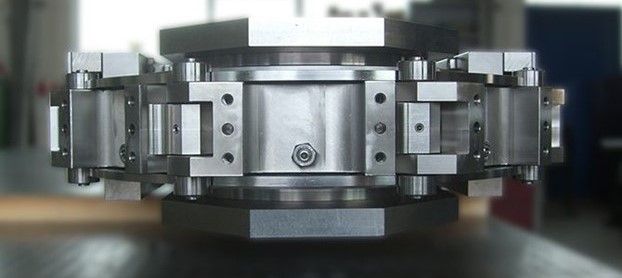

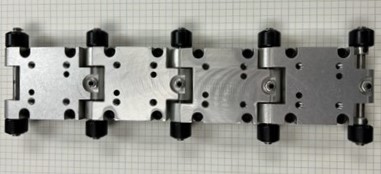

Some competitive conveyor systems rely on a continuous strip of metal or a continuous length of small pitch chain on which their pallet/fixture is mounted. This approach results in a loss of location accuracy over time, due to stretching of the mount material. Every Swanson precision-link conveyor consists of one continuous run of high-precision links. There is no loss of accuracy, as there is no component that can stretch. Each link contains eight cam rollers that guide the link along proprietary hardened and ground guide rails. Our cam followers are sealed and lubed for life.

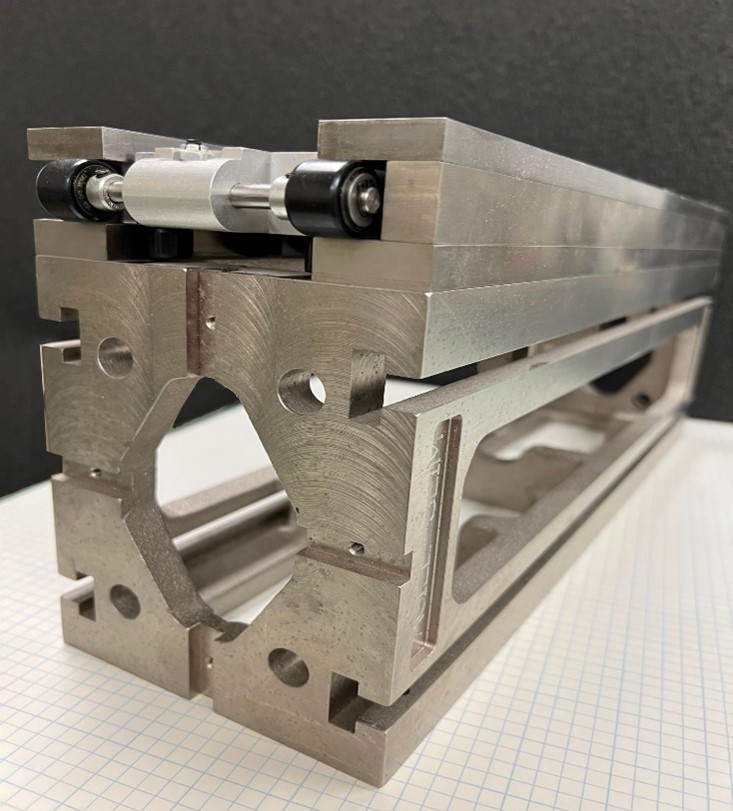

The Swanson precision-link conveyor frames are made of cast iron modules to deaden vibration and allow for increased precision modular tooling design. The link track is made of machined and hardened ground steel, resulting in years of trouble-free production. This inner structure, made of precision machined cast iron offers distinct customer benefits. The precise full length mounting surfaces provide ideal low vibration platforms for customer supplied station tooling.

Our Precision Links are offered in a variety of materials from basic high strength aluminum alloys to other materials that may suit the application demands better.

Several reliable drive options are available to power the chain on a precision-link conveyor. Either a hardened cam indexer or a programmable drive based on servo motor technology are routinely used. If a cam indexer is used, one index cycle can spur any number of link stroke lengths, ranging from a few millimeters to a meter. No matter the drive, Swanson Precision Link Conveyors can be setup for intermittent or continuous motion.

At the often-neglected non drive, or idle end of the conveyor circuit, a hardened and preloaded cam surface guides the chain and provides “take-up” to prevent chain backlash at the link connections. This often-overlooked design detail provides extended conveyor accuracy and extended conveyor life.

Customized precision-link conveyors are manufactured to meet specific customer project requirements. Non-standard requests receive support beginning with the project design phase, resulting in final conveyors that may include specialty drive units, tailored frame shapes, custom pitches & strokes, tapped holes, mounting plates, through holes in the chassis, or custom coatings on the components.

Swanson Precision Link indexing conveyors are well suitable for high-speed assembly of components, especially when there are many parts to assemble or there are complicated assembly processes. Work processes are usually performed along the conveyor’s linear sections. Simple operations can be performed on the radial end sections if space or budget are limited.

The Swanson Precision Link conveyor is regularly used for manufacturing in aerospace, solar energy, wind energy, automotive, defense, electronics, consumer goods, and medical devices. Precision Link conveyors are fast and accurate. They provide fixture positioning for assembly (and other tasks) up to 300 parts per minute. That is made possible when the conveyor is driven by direct linkage to a servomotor or cam-controlled indexer. Precision Link conveyors advance the fixtures precisely, without the need for additional positioning devices to locate fixtured parts before the manufacturing process is initiated.

Precision Link conveyors allow automated processes right on the conveyor. After each indexed stroke (to advance the links) equipment mounted around the conveyor executes parallel and serial tasks. Most installations include multiple workstations along one or both linear conveyor axes. The workstations can be servo driven stations or mechanically cam driven with synchronous line shafts or a hybrid of mechanical and servo.

Precision Link Conveyors are designed to run high volume manufacturing for millions of cycles without intensive maintenance. This conveyor type is designed and engineered to be the core product-positioning chassis for machines executing critical functions. Swanson Precision Link Conveyors are available in a large variety of Metric or English link lengths & widths. Fixture loads vary from less than 1 pound per link to loads of 75 pounds per link. The conveyor can index intermittently or run continuously.

Swanson builds the best Precision Link Chassis for your application.