Why Swanson Precision Link Agile Chassis?

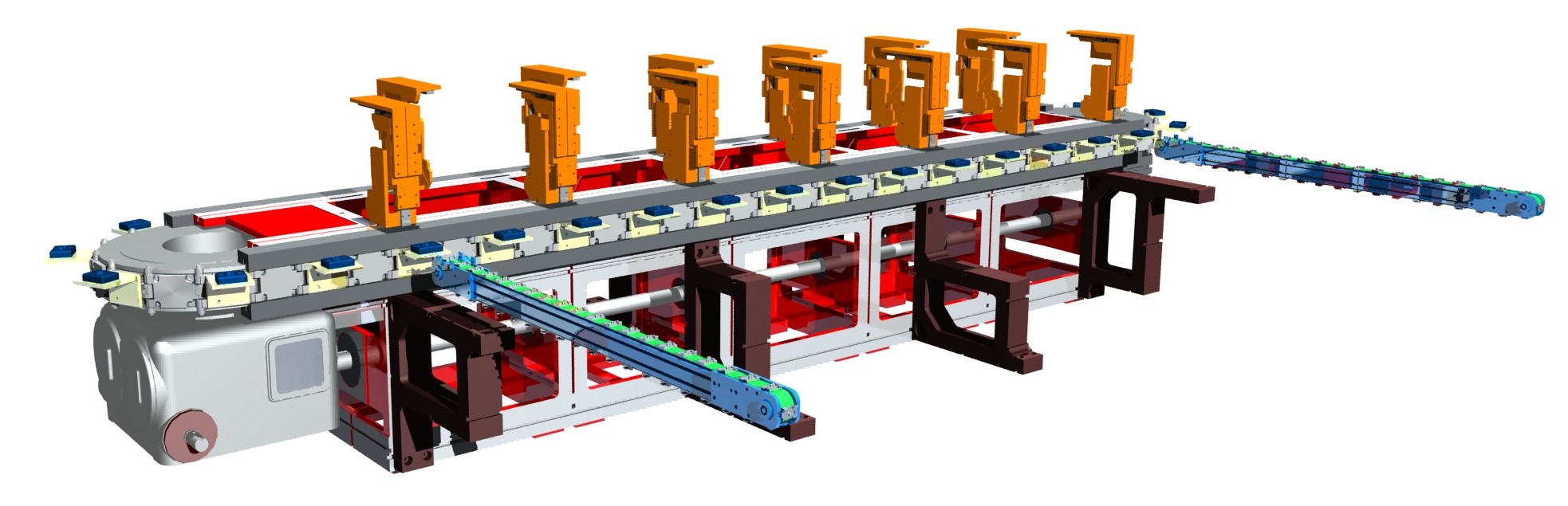

The Swanson Precision Link Agile Chassis is the newest and most novel machine chassis concept to be developed in the last 20 years. It totally changes the way machines are conceived. The result is simplicity, adaptability, and re-deployability. Major savings in design and development costs result while producing a more rigid, precise, and versatile machine.

The simplicity of precision “modules” being used to design and build machines means that the project cost goes where there is functional value and not into irretrievable first-time design, build, and debug costs. To be able to expand the conveyor length on short notice gives flexibility during the design and development phases of the program.

Best of all, these components can be used over again. Interchangeability is warranted and is permanently recorded by individual component serial numbers. With the Precision Link Agile Chassis components there are no more “bone yards” of unusable old equipment, future machines are possible with minimal chassis cost. Designers now design with modern CAD and 3D technology. With Agile Chassis components a machine can be laid out in hours, not weeks or months. The Agile Chassis helps make programs more “sellable” to management and those in financial control.

The chassis is attractive, functional, affordable, adaptable, and exciting. Give us a call. Let us help you on your next project.